VR-Tracked Robotic Fabrication of Brick Wall

Background

In this project, my role is to fabricate a fundraising brick wall on-site and developed a real-time positioning system that integrates the HTC VIVE Tracker with a UR10 robotic arm.

The work began with two challenges:

- How to reposition a robotic system on a construction site, and

- How to use VR-based tracking to locate building components in situ?

On-Site Robotic Setup

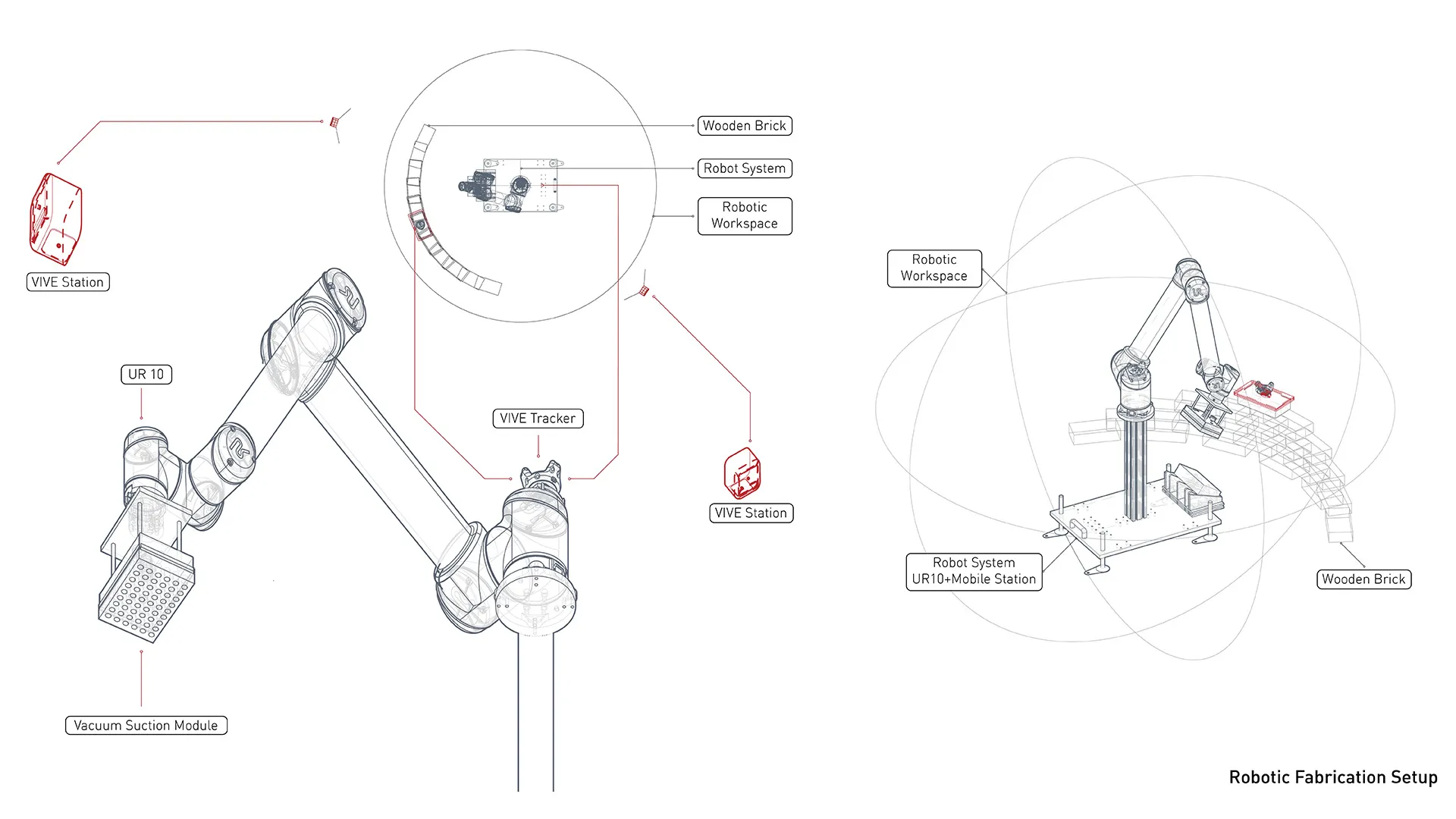

The UR10 robotic arm was mounted on a mobile station for on-site deployment. A pickup area for 20×10×5 cm wooden bricks was integrated at the base of the station.

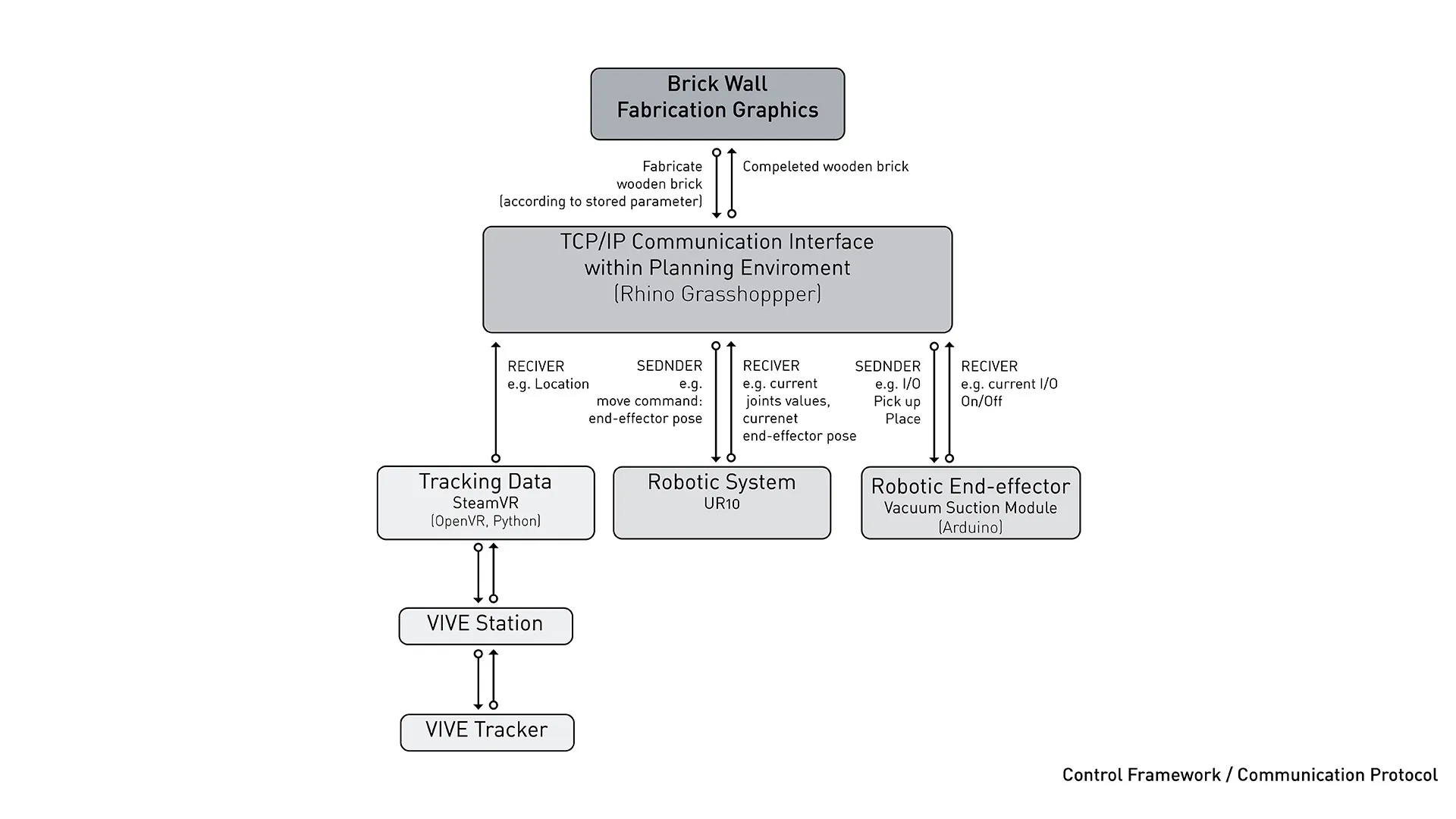

VR–Robotics Integration Pipeline

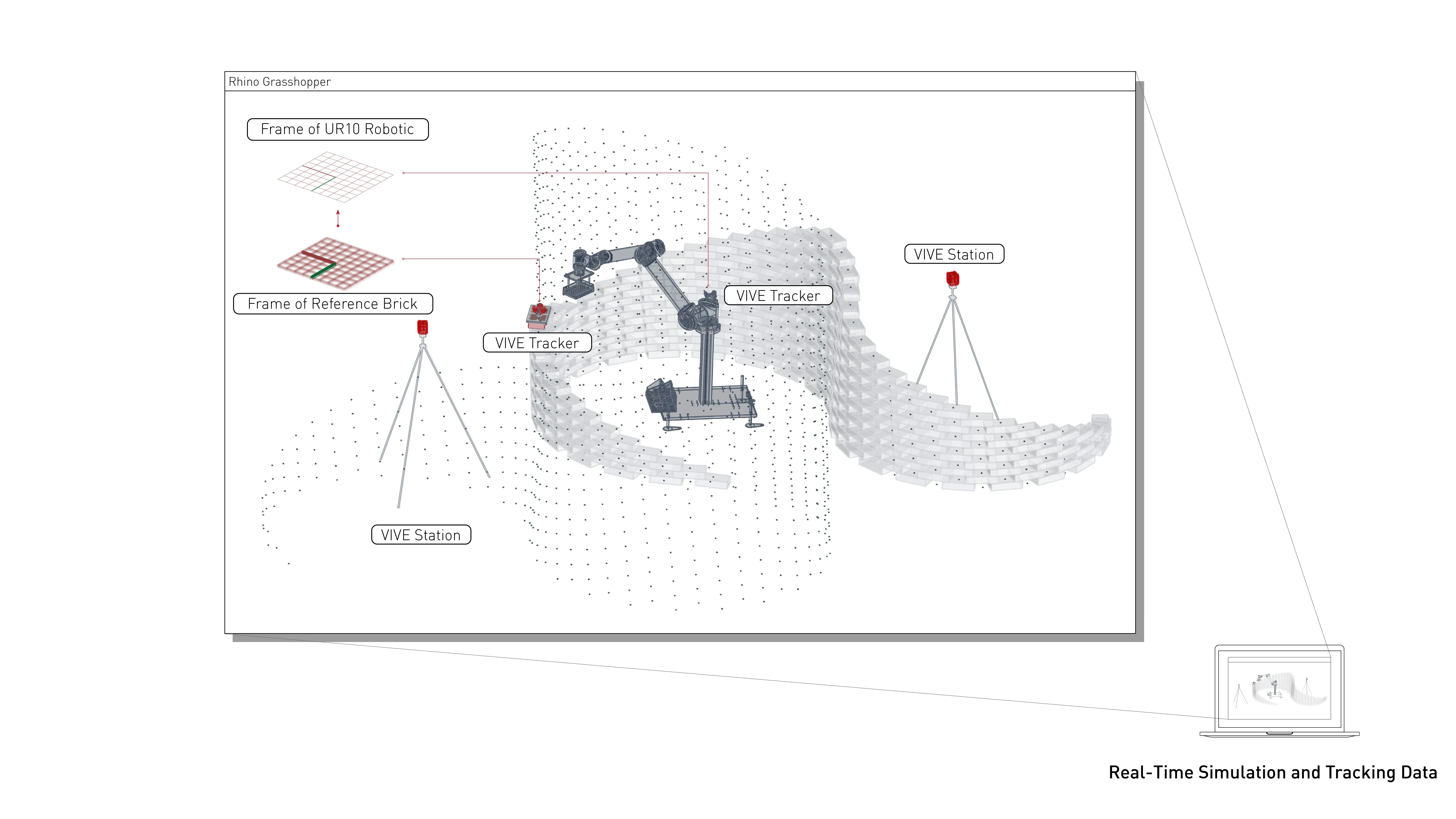

HTC VIVE tracking was used to collect real-time positional data. Using Rhino3D, Grasshopper3D, SteamVR, OpenVR, and Python, we created a virtual environment that synchronized with the physical site.

Robotic Fabrication Simulation

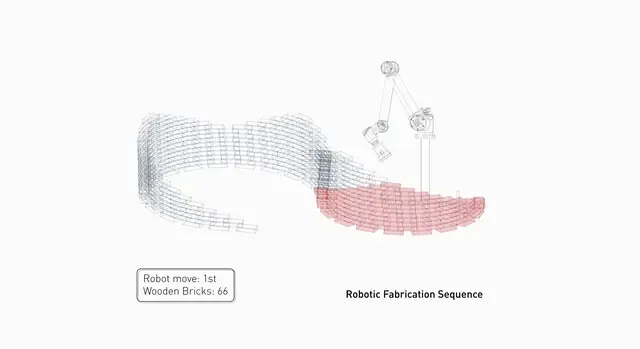

The VIVE Tracker provided relative coordinates between the UR10 and a reference block. This data allowed us to simulate and execute the fabrication process: each cycle placed 80–120 bricks within 1–2 hours, ensuring the UR10 avoided collisions. Once an area was completed, the robot was repositioned to continue the build.

Construction Sequence

Throughout construction, the UR10 was repositioned 22 times to complete 24 layers totaling 1024 bricks. Due to ceiling height limitations, the remaining 28 layers (406 bricks) were assembled using prefabricated components.

Welcome to watch the video below.

Team

Prof. Chen-Cheng Chen, You-Wen Ji, Ying-Shiuan Chen, Ching-Yin Wang